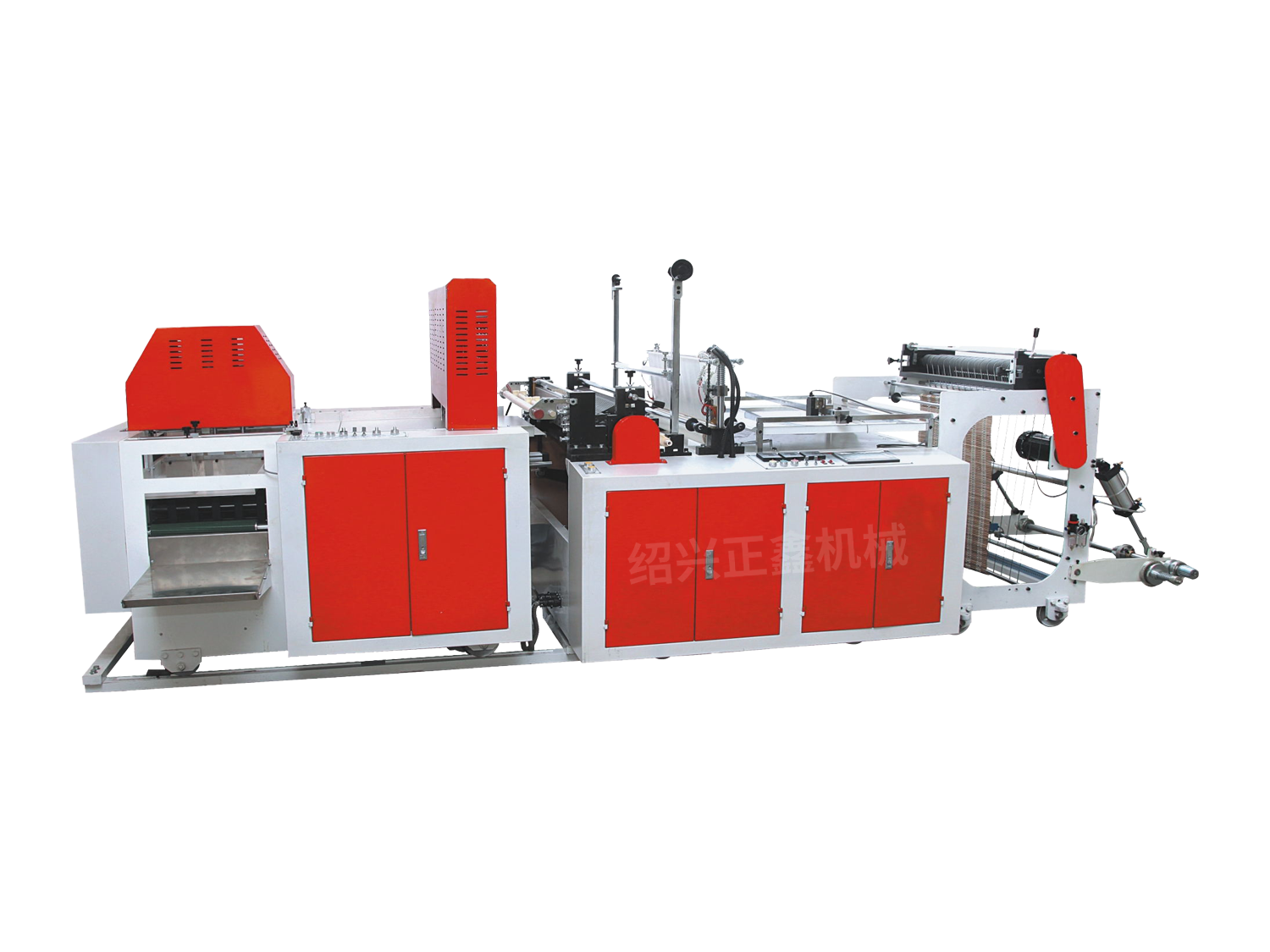

Several common problems and countermeasures of bag making machine (Part 2)

The bag making machine is a machine for making various plastic packaging or other material packaging bags. Its processing range is various sizes of plastic or other material packaging bags with different thickness and specifications. Of course, there will be many problems during the use of the bag making machine. This article is to help you eliminate the troubles about the use of the bag making machine.

7. What should I do if the finished products cut out by the side sealing machine are of different lengths?

The rubber roller slipped because the pressure spring was not compressed, or the clamping plate behind was too tight, so it needs to be adjusted properly.

8. What to do if the flat mouth machine is blocked in front of the cold cutter

In this case, it should be that the bag is too strong. Use a rubber band to attach a small piece of paper to the screw on the knife beam. Cut out the tape and snap the bag down at the same time.

9. What should I do if the thickness of the film blowing machine is uneven and one side is thin?

It needs to be wrapped around the electronic frame on the thin side until it fits.

10. What should I do if the feeding of the printing bag is not smooth and the electric eye is not sensitive enough?

First check whether the electric eye is used correctly. The electric eye has a certain degree of sensitivity to color. If the bag is a single color, use blue, and use red for heavy color. Red can be used for single color and heavy color. The roller under the electric eye of the edge correcting machine should be sprayed black. If the color of the bag is single and heavy, it is best to use a white background.

11. The new machine has not been cutting bags for a long time, what should I do if the cutter keeps cutting thinner films or a certain place?

This situation may be caused by the fact that after a period of running-in of the upper knife beam slider, the gap between the slider and the copper pad is too large, which in turn causes the cutter to cut continuously. The top seam (M6 inner corner) of the copper pad can be adjusted until the slider of the upper knife beam cannot be shaken by hand, but it cannot be adjusted too tight. When the machine is turned on and cuts 15-20 sheets per minute, there is no obvious vibration of the upper knife beam, which proves that the gap is just right. In addition, the spring pressure of the upper beam can be adjusted.

12. What should I do if the seal of flat mouth machine and R machine is not firm?

① Check whether the hot knife is jammed: the hot knife is not sealing and cutting smoothly, which will cause the seal to be sometimes firm and sometimes not firm.

② Check whether the knife edge is deformed or bent due to heating. The inspection method is to turn the hot knife to the bottom position, when the hot knife is just about to connect

When touching the silicone roller or silicone plate, use the light transmission method to judge whether the hot knife is bent. If there is bending, repair the flatness of the knife edge

③ Check whether the electron passing through the film is too strong. Test it with a film that has not passed through electrons. If it is sealed, see if there is any obvious change in the seal. If so, it proves that the film passing through the film is too strong. It is recommended to change the material.

English

English 简体中文

简体中文