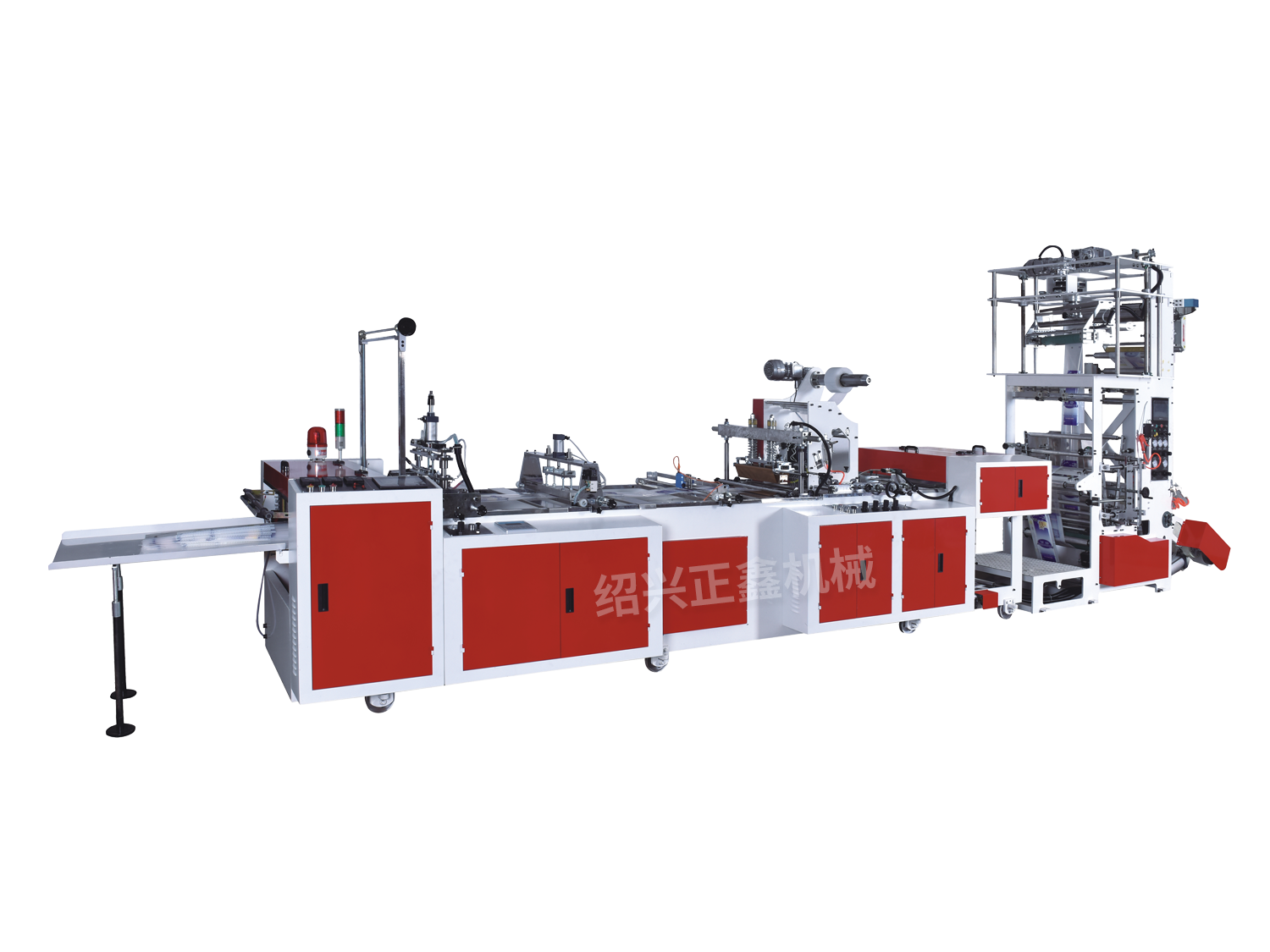

Revolutionizing Packaging Efficiency: Gusseting and Bag Making All-in-One Machine

In the world of packaging, efficiency and productivity are key factors that determine success. Manufacturers are constantly looking for innovative solutions to streamline their processes and maximize output. One groundbreaking machine that has taken the packaging industry by storm is the Gusseting and Bag Making All-in-One Machine.

Traditionally, gusseting and bag making were separate processes that required different machines and setups, resulting in increased labor, time, and resources. However, with the advent of the Gusseting and Bag Making All-in-One Machine, manufacturers can now enjoy the benefits of combining these two essential functions into a single, efficient solution.

This all-in-one machine offers a range of benefits that positively impact production efficiency. First and foremost, it eliminates the need for multiple machines, freeing up valuable floor in the production area. Manufacturers can now optimize their workspace and allocate resources more effectively.

Moreover, the Gusseting Bag Making All-in-One Machine significantly reduces setup time and simplifies the operation process. By eliminating the need to switch between machines, operators can seamlessly transition from gusseting to bag making, reducing downtime and increasing overall productivity. This streamlined workflow ensures a smoother and faster production cycle, ultimately improving output and profitability.

The versatility of this all-in-one machine is another advantage. It can handle various materials, including films, foils, and laminates, catering to a wide range of packaging needs. Whether producing bags for food items, pharmaceuticals, or consumer goods, the machine ensures consistent quality and precise gusseting and bag making every time.

Furthermore, the Gusseting and Bag Making All-in-One Machine incorporates advanced technology and features that enhance the overall packaging process. It offers precise control over the gusseting and bag making parameters, such as width, depth, and sealing. This level of control ensures the production of high-quality bags that meet strict industry standards.

Additionally, the machine often utilizes state-of-the-art sensors and automated systems to detect and correct any discrepancies during the packaging process. This ensures that each bag is made with precision, minimizing the risk of errors or product wastage. Manufacturers can have peace of mind, knowing that their products are packaged flawlessly, enhancing customer satisfaction and brand reputation.

From a sustainability standpoint, the Gusseting and Bag Making All-in-One Machine contributes to reducing waste and environmental impact. The precise control over materials and sealing ensures minimal material usage and efficient use of resources. With sustainability becoming an increasingly important concern for consumers and businesses alike, this machine aligns with eco-conscious initiatives in the packaging industry.

In conclusion, the Gusseting and Bag Making All-in-One Machine marks a significant advancement in the packaging sector, revolutionizing the way manufacturers approach gusseting and bag making processes. By combining these functions into a single, efficient machine, manufacturers benefit from improved productivity, versatility, precision, and sustainability. Embracing this technology allows businesses to stay ahead of the competition, deliver superior packaging solutions, and maximize efficiency in a rapidly evolving industry.

English

English 简体中文

简体中文