Maximizing Productivity: The Integrated Gusseting and Bag Making Machine

In today's fast-paced manufacturing landscape, optimizing productivity and efficiency is a crucial factor for success. Industries that rely on the production of bags, especially in packaging and retail sectors, are constantly seeking innovative solutions to streamline their processes and reduce costs while maintaining product quality. One such revolutionary solution is the Integrated Gusseting and Bag Making Machine.

Traditional bag manufacturing processes involve several steps, each requiring specialized machinery and skilled operators. Gusseting, a process that creates pleats or folds in the sides of a bag, adds structural stability and increased capacity to bags. Historically, gusseting was a separate step in bag production, which required additional machinery, labor, and time. The integration of gusseting into the bag making machine is a game-changer that eliminates the need for a separate gusseting machine and reduces the overall manufacturing time.

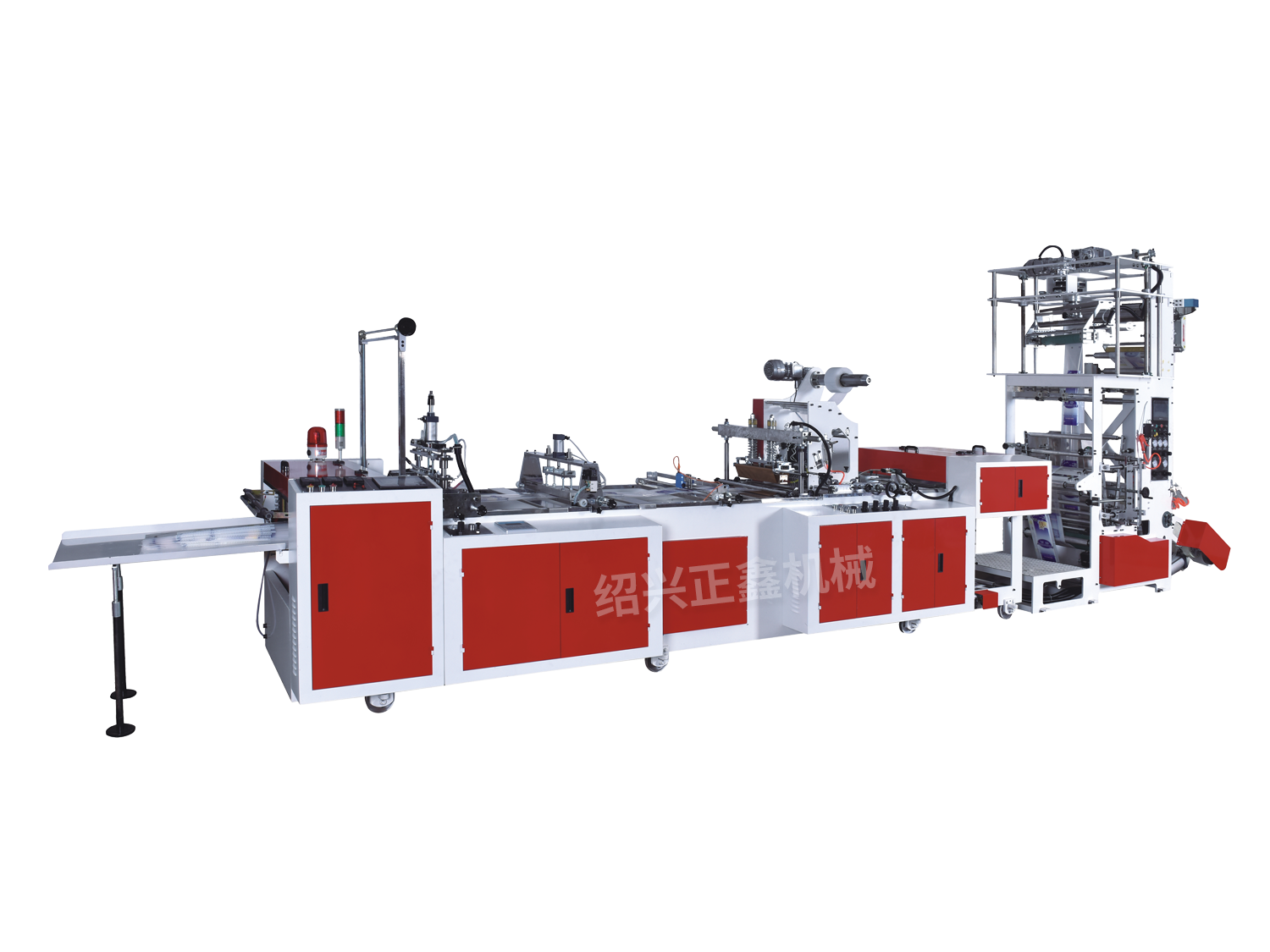

The Integrated Gusseting and Bag Making Machine brings together multiple functions that were once carried out sequentially. This innovative machine combines the processes of cutting, gusseting, and sealing in one continuous operation. The material is fed into the machine, and through a series of precision movements and adjustments, it is transformed into a finished bag with gussets. This integration not only saves time but also minimizes material handling, reducing the risk of errors and waste.

One of the key advantages of this integrated machine is its impact on productivity. Manufacturers can produce a higher volume of gusseted bags in a shorter amount of time, meeting market demands more effectively. The streamlined process also translates to cost savings, as fewer operators are required to oversee the production line, and the energy consumption of a single integrated machine is typically lower than that of multiple standalone machines.

Quality control is another area where the integrated machine shines. With a reduction in manual interventions and transitions between machines, there's a decreased likelihood of defects or inconsistencies in the final product. The machine's precision and automation ensure that each bag is consistently gusseted and sealed to the highest standards.

Training operators to use the integrated machine is generally less complex than training them to operate multiple separate machines. The intuitive interface and centralized controls contribute to a shorter learning curve, allowing manufacturers to onboard new operators more efficiently and effectively.

Furthermore, the integrated machine's compact design optimizes floor space utilization. Manufacturers can make better use of their factory layout, potentially freeing up space for other essential processes or machinery. This efficient space management has the potential to improve overall factory organization and workflow.

In conclusion, the Integrated Gusseting and Bag Making Machine marks a significant advancement in the field of bag manufacturing. By combining the processes of gusseting, cutting, and sealing into a single, streamlined operation, manufacturers can maximize productivity, reduce costs, and enhance product quality. The integration of these functions not only saves time and labor but also contributes to a more sustainable manufacturing process with lower energy consumption and reduced material waste. As industries continue to evolve and seek efficient solutions, the integrated gusseting and bag making machine stands as a shining example of innovation that propels manufacturing into a more productive and profitable future.

English

English 简体中文

简体中文