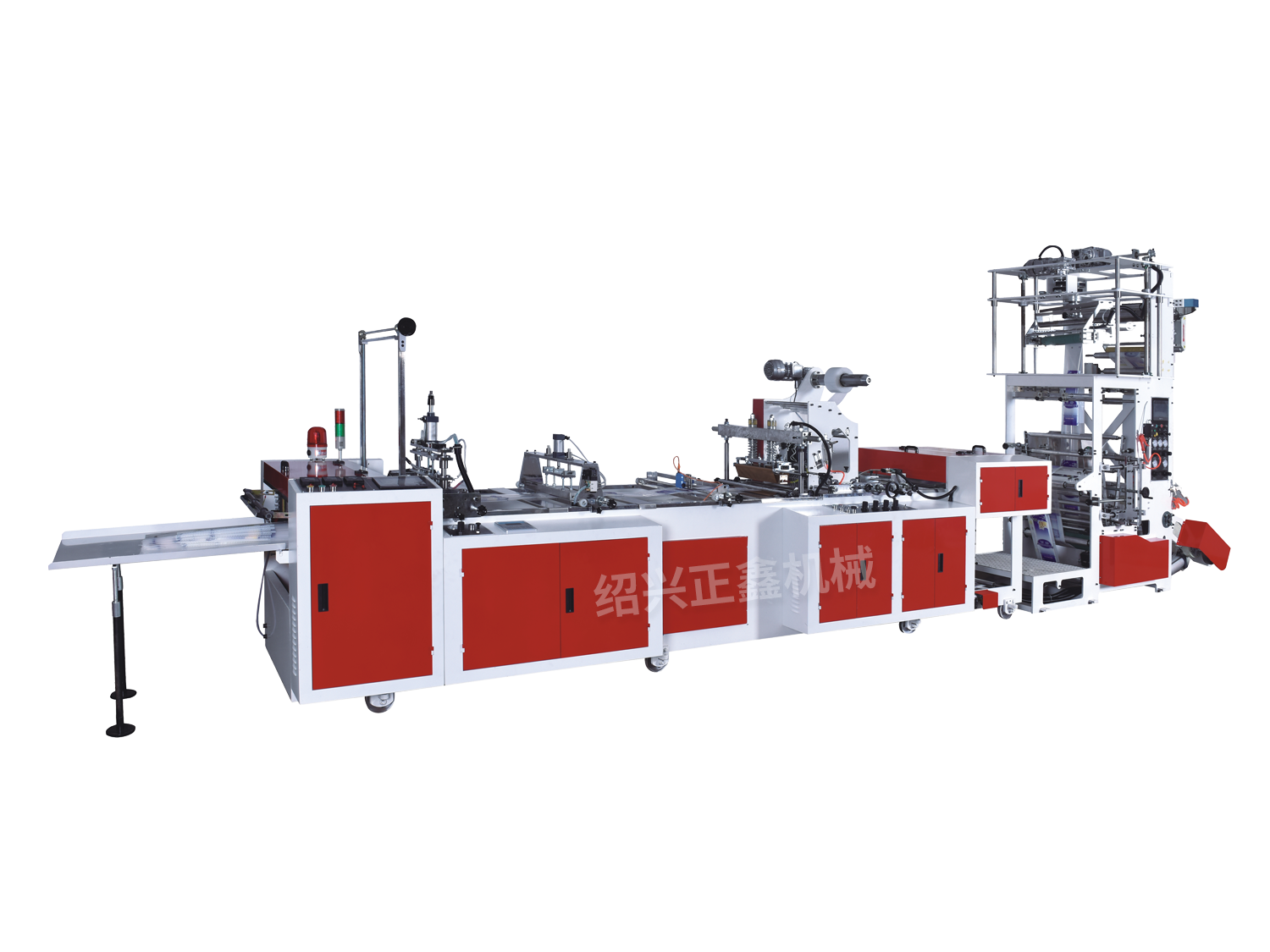

Material Utilization Advantages and Waste Minimization Technology of Gussetting and Bag Making All-in-One Machine

Gussetting and Bag Making All-in-One Machine, as an advanced bag making equipment, not only performs well in improving production efficiency, but also shows significant advantages in material utilization. This article takes an in-depth look at how this machine can minimize material waste and improve the economics of the bag making process.

1. Material optimization design:

The design of Gussetting and Bag Making All-in-One Machine focuses on the optimal utilization of materials. Through sophisticated algorithms and control systems, it ensures that every inch of material is fully utilized and minimizes waste generation.

2. Automatic adjustment function:

This kind of machine is usually equipped with an automatic adjustment function, which can automatically adjust the cutting and folding positions according to the size, shape and material of the bag, avoiding excessive material waste and improving material utilization.

3. Precise positioning technology:

Advanced precision positioning technology is used to ensure the accurate position of the knife and folding parts, precise cutting and folding, reducing errors and further reducing waste generation.

4. Intelligent control system:

The intelligent control system of the Gussetting and Bag Making All-in-One Machine can monitor the bag making process in real time, adjust the working methods of knives and folding parts according to production needs, optimize the use of materials, and avoid unnecessary waste.

5. Forward-looking sensing technology:

Some advanced machines use forward-looking sensing technology to identify possible problems in advance and make intelligent adjustments during the cutting and folding processes to ensure optimal material utilization in each bag-making cycle.

6. Intelligent layout algorithm:

The machine uses an intelligent layout algorithm to optimize the placement of fabrics according to the shape and size of the bag, ensuring that fabric utilization is maximized and waste is minimized in each bag making cycle.

7. Waste recycling system:

Some advanced Gussetting and Bag Making All-in-One Machines are also equipped with waste recycling systems to further reduce the waste of raw materials by reprocessing or recycling waste materials.

8. Real-time data monitoring:

Machines are usually equipped with real-time data monitoring functions and use data analysis technology to continuously optimize the bag making process, improve material utilization, and reduce production costs.

9. Environmental awareness:

The advantage in material utilization also reflects the Gussetting and Bag Making All-in-One Machine's focus on environmental protection, reducing waste generation and in line with the concept of sustainable development.

10. User training and support:

In order to give full play to the material utilization advantages of the machine, manufacturers usually provide professional user training and technical support to ensure that operators can fully understand and rationally use the various functions of the machine.

Gussetting and Bag Making All-in-One Machine not only improves production efficiency through its excellent material utilization, but also saves raw material costs for enterprises, achieving a win-win situation of sustainable development and economic benefits. In the future, as technology continues to upgrade, such machines will continue to bring more innovation and development to the bag making industry.

English

English 简体中文

简体中文